-

Cable Impedance Test Set Z-OVR

0 AED (Incl 5 VAT)

-

Secondary Current Injection Test kit 100ADM MK4

0 AED (Incl 5 VAT)

-

Secondary Current Injection Test Set 50A-3PH MK2

0 AED (Incl 5 VAT)

-

Digital Low Resistance Ohmmeter DMO600

0 AED (Incl 5 VAT)

-

High Voltage AC Test Set KV30-40D MK2

0 AED (Incl 5 VAT)

-

KV15-80D AC Test System

0 AED (Incl 5 VAT)

-

High Voltage DC Tester PT30-10 MK2 30kV 10mA

0 AED (Incl 5 VAT)

-

High Voltage DC Tester PT18-10 MK2 18kV 10mA

0 AED (Incl 5 VAT)

-

High Voltage DC Tester PT15-10S 15kV 10mA

0 AED (Incl 5 VAT)

-

Primary Current Injection Test Set PCU1-SP MK2 5000A

0 AED (Incl 5 VAT)

-

Secondary Current Injection Test Set 200A-3PH MK2

0 AED (Incl 5 VAT)

-

Primary Current Injection Test Set 750ADM-H MK2

0 AED (Incl 5 VAT)

-

Hipot Tester KV5-100 MK2

25800 AED (Incl 5 VAT)

-

Hot Wire Anemometer with Telescopic Articulating Probe 6036

4800 AED (Incl 5 VAT)

-

Multi Function Hot-Wire Anemometer

4800 AED (Incl 5 VAT)

-

Anemometer Data Logger - 850023

1300 AED (Incl 5 VAT)

-

Bluetooth Anemometer - 850020

315 AED (Incl 5 VAT)

-

Environmental Quality Meter 12-IN-1 850027

840 AED (Incl 5 VAT)

-

850070-Mini Environmental Quality Meter

900 AED (Incl 5 VAT)

-

Multifunction Anemometer - 850026

510 AED (Incl 5 VAT)

-

Anemometer-850025

430 AED (Incl 5 VAT)

-

Tabmaster Airflow Capture Hood 6710

8600 AED (Incl 5 VAT)

-

Air Flow Balometer Capture Hood - 6715

10200 AED (Incl 5 VAT)

-

Airflow Balometer TABmaster Mini Hood

0 AED (Incl 5 VAT)

-

Handheld Micromanometer Kanomax 6850

5200 AED (Incl 5 VAT)

-

5 3/4 digital High Precision Multimeter

900 AED (Incl 5 VAT)

-

Type K Immersion Thermometer Probe 800060

170 AED (Incl 5 VAT)

-

Large Type K Immersion Thermometer Probe 800061

180 AED (Incl 5 VAT)

-

Digital Clamp Meter 1000 Amp AC/DC DL6402

480 AED (Incl 5 VAT)

-

1500A AC/DC True RMS Power Clamp Meter with Inrush Current - DL6508

840 AED (Incl 5 VAT)

-

AC Leakage Clamp Meter with 10 µA - 1000 A - DL6519

1700 AED (Incl 5 VAT)

-

DL6518 AC Leakage Clamp Meter

1300 AED (Incl 5 VAT)

-

Advanced Multi Function Tester DL9118

3400 AED (Incl 5 VAT)

-

Phase & Motor Rotation Meter DL9020N

520 AED (Incl 5 VAT)

-

Phase sequence meter-HT82

525 AED (Incl 5 VAT)

-

Laser Distance Meter PCE-LDM 45

225 AED (Incl 5 VAT)

-

DL9050N Insulation Continuity Tester

950 AED (Incl 5 VAT)

-

Insulation Multimeter Tester c/w Bar Graph DL9307

1425 AED (Incl 5 VAT)

-

DL9062 Earth Resistance Tester

1200 AED (Incl 5 VAT)

-

Proving Unit Testers PU690

560 AED (Incl 5 VAT)

-

DL9206 Compact Auto Ranging Multimeter

350 AED (Incl 5 VAT)

-

DL9205 Compact Ranging Multimeters

300 AED (Incl 5 VAT)

-

DL9204 Compact Ranging Multimeters

220 AED (Incl 5 VAT)

-

DL114 Mini Digital Multimeter

220 AED (Incl 5 VAT)

-

DL9309 True RMS Multimeter

750 AED (Incl 5 VAT)

-

DL9308 True RMS Multimeter

700 AED (Incl 5 VAT)

-

DL9101 Manual Ranging Multimeters

340 AED (Incl 5 VAT)

-

PL280N Digital Multimeters

250 AED (Incl 5 VAT)

-

Rotating Vane Anemometer 6822

4800 AED (Incl 5 VAT)

-

TE-350P - Dry Block Calibrators

10800 AED (Incl 5 VAT)

-

TE-650P - Dry Block Calibrators

12240 AED (Incl 5 VAT)

-

TE-1200P - Dry Block Calibrators

19200 AED (Incl 5 VAT)

-

T-30NIR - Infrared Calibrator

18400 AED (Incl 5 VAT)

-

T-500PIR - Infrared Calibrator

16800 AED (Incl 5 VAT)

-

T-1200PIR - Infrared Calibrator

22800 AED (Incl 5 VAT)

-

Hot Wire Anemometer SD Card Logger 850024

1800 AED (Incl 5 VAT)

-

WBGT Meter with Color-Coded LCD 801038

800 AED (Incl 5 VAT)

-

WBGT Heat Stress Meter 800036

520 AED (Incl 5 VAT)

-

Heat Stress Monitor - 800034

400 AED (Incl 5 VAT)

-

Scanning Moisture Meter - 850002

630 AED (Incl 5 VAT)

-

Moisture Meter - 850001

480 AED (Incl 5 VAT)

-

Digital Low Resistance Micro-Ohmmeter DMO200

0 AED (Incl 5 VAT)

-

DL7101 Digital Thermometer

490 AED (Incl 5 VAT)

-

UV Light Meter Stellar Instruments SI240

800 AED (Incl 5 VAT)

-

850006-LED Light Meter with Color Temperature Compensation

850 AED (Incl 5 VAT)

-

850005-Advanced Visible Light SD Card Logger

1150 AED (Incl 5 VAT)

-

Light Meter 850004

320 AED (Incl 5 VAT)

-

850007-Visible Light SD Card Logger

825 AED (Incl 5 VAT)

-

DL7105 Infrared Thermometer

820 AED (Incl 5 VAT)

-

Light Meter Lux/FC - 840020

540 AED (Incl 5 VAT)

-

Digital Thermometer Set 94029

850 AED (Incl 5 VAT)

-

Digital Humidity & Temperature Meter- DL7102

520 AED (Incl 5 VAT)

-

840006-Light Meter Lux

450 AED (Incl 5 VAT)

-

840021-Light Meter FC

400 AED (Incl 5 VAT)

-

Digital Sound Level Meter - DL7103

600 AED (Incl 5 VAT)

-

DL1092 - Advanced RCD Electric Socket Tester

180 AED (Incl 5 VAT)

-

DL1090 - Socket Tester c/w Buzzer

105 AED (Incl 5 VAT)

-

DL6799 - Voltage, Continuity & Current Tester

550 AED (Incl 5 VAT)

-

Voltage Indicator with Phase Rotation Test DL6790

220 AED (Incl 5 VAT)

-

Voltage Continuity Tester DL6770

160 AED (Incl 5 VAT)

-

Sound Meter Type 1 - 840015

1200 AED (Incl 5 VAT)

-

Non Contact Voltage Detector DL108

110 AED (Incl 5 VAT)

-

Non-Contact Voltage Detector DL107

100 AED (Incl 5 VAT)

-

Environmental Quality Meter with Sound 850069

1200 AED (Incl 5 VAT)

-

850016 Acoustical Calibrator

800 AED (Incl 5 VAT)

-

Graphic Display Sound Meter - 850015

840 AED (Incl 5 VAT)

-

Mini Sound Meter - 850014

525 AED (Incl 5 VAT)

-

Sound Level Pen - 840018

500 AED (Incl 5 VAT)

-

Indoor Air Quality Controller - 800045

640 AED (Incl 5 VAT)

-

Duct Air Leakage Tester - DALT 6900

32000 AED (Incl 5 VAT)

-

Hand held Air Quality Meter - 2700

0 AED (Incl 5 VAT)

-

Handheld Particle Counter - Kanomax 3888

10200 AED (Incl 5 VAT)

-

6 Channel Particle Counter - Kanomax 3889

14500 AED (Incl 5 VAT)

-

Holiday Detector 1-5kV DC MODEL 780

15550 AED (Incl 5 VAT)

-

Holiday Detector 1-15kV MODEL 785

15500 AED (Incl 5 VAT)

-

Holiday Detector 5-35 kV MODEL 790

15900 AED (Incl 5 VAT)

-

Solar Irradiance Meter with Multimeter - SL102

600 AED (Incl 5 VAT)

-

Compact Digital Irradiance Meter SL101

520 AED (Incl 5 VAT)

-

40kV SPY Jeep Meter Model JM

5400 AED (Incl 5 VAT)

-

20 kV SPY Jeep Meter

0 AED (Incl 5 VAT)

-

5 kV SPY Jeep Meter DCPJM

0 AED (Incl 5 VAT)

-

SPY Low Voltage Wet Sponge

0 AED (Incl 5 VAT)

-

5kV INPLANT DC HOLIDAY DETECTOR

0 AED (Incl 5 VAT)

-

25kV INPLANT PULSE HOLIDAY DETECTOR

0 AED (Incl 5 VAT)

-

35kV INPLANT PULSE HOLIDAY DETECTOR

0 AED (Incl 5 VAT)

-

SPY PT-101 PIG Tracker Transmitter

0 AED (Incl 5 VAT)

-

15 kV MD-15kVR Digital Insulation Tester

19500 AED (Incl 5 VAT)

-

Food Safety Thermometer- 800115

420 AED (Incl 5 VAT)

-

800254-Wireless Humidity/Temperature Monitor Set

600 AED (Incl 5 VAT)

-

I-V Curve Tracer I-V500W

16800 AED (Incl 5 VAT)

-

SOLAR I-Ve Multifunction I-V Curve Tracer

0 AED (Incl 5 VAT)

-

PVChecks- Multifunction Device for PV System

8400 AED (Incl 5 VAT)

-

800015-Humidity/Temperature Monitor with Remote Temperature

190 AED (Incl 5 VAT)

-

800255-Additional Wireless Humidity/Temperature Sensor

300 AED (Incl 5 VAT)

-

dpm TT 550 S Micromanometer 0.01 pa Resolution

5475 AED (Incl 5 VAT)

-

Humidity Temperature Monitor 800016

170 AED (Incl 5 VAT)

-

Indoor Outdoor Humidity Temperature Monitor with Remote 800027

220 AED (Incl 5 VAT)

-

Portable Appliance TEST DLPT2+ Kit

3700 AED (Incl 5 VAT)

-

2 Channel Thermocouple Thermometer- 800007

340 AED (Incl 5 VAT)

-

Basic Thermocouple Thermometer- 800004

375 AED (Incl 5 VAT)

-

800120-Clinical Grade Infrared Non-Contact Thermometer

350 AED (Incl 5 VAT)

-

Infrared Thermometer with Dew Point - 800111

520 AED (Incl 5 VAT)

-

800106-Infrared Thermometer Gun with Alarm 12:1 / 1400ºF

525 AED (Incl 5 VAT)

-

Infrared Thermometer Gun 12:1- 800103

380 AED (Incl 5 VAT)

-

800102-Infrared Thermometer Gun 8:1 / 930°F

275 AED (Incl 5 VAT)

-

800101-Infrared Thermometer Gun 8:1 / 605°F

245 AED (Incl 5 VAT)

-

4 Channel Thermocouple Thermometer Datalogging

1110 AED (Incl 5 VAT)

-

Thermocouple Thermometer Datalogger - 800008

900 AED (Incl 5 VAT)

-

Four Channel Thermometer - 800023

650 AED (Incl 5 VAT)

-

800005-Advanced Thermocouple Probe Thermometer Type K/J

475 AED (Incl 5 VAT)

-

800118C-Datalogging RTD Thermometer - Certified

1675 AED (Incl 5 VAT)

-

HACCP Thermometer - 800042

940 AED (Incl 0 VAT)

-

Waterproof RTD Thermometer - 800117C

910 AED (Incl 5 VAT)

-

Handheld Tachometer PCE-DT65

600 AED (Incl 5 VAT)

-

Tachometer-Stroboscope PCE-T 260

1460 AED (Incl 5 VAT)

-

TRM Digital Multimeter - Flashmeter

445 AED (Incl 5 VAT)

-

Pocket digital multimeter with integrated AC/DC 60A clamp meter

0 AED (Incl 5 VAT)

-

Thermo-Hygrometer PCE-444

160 AED (Incl 5 VAT)

-

Mini Anemometer PCE-MAM 2

180 AED (Incl 5 VAT)

-

HANDHELD ODOR METERS OMX - ADM

0 AED (Incl 5 VAT)

-

HANDHELD ODOR METERS OMX - TDM

0 AED (Incl 5 VAT)

-

TRMS AC/DC Digital Multimeter 600V - HT211

480 AED (Incl 5 VAT)

-

Compact Digital Multimeters HT25N

375 AED (Incl 5 VAT)

-

Dust Monitor Model 3521 & 3522 - Kanomax - USA

0 AED (Incl 5 VAT)

-

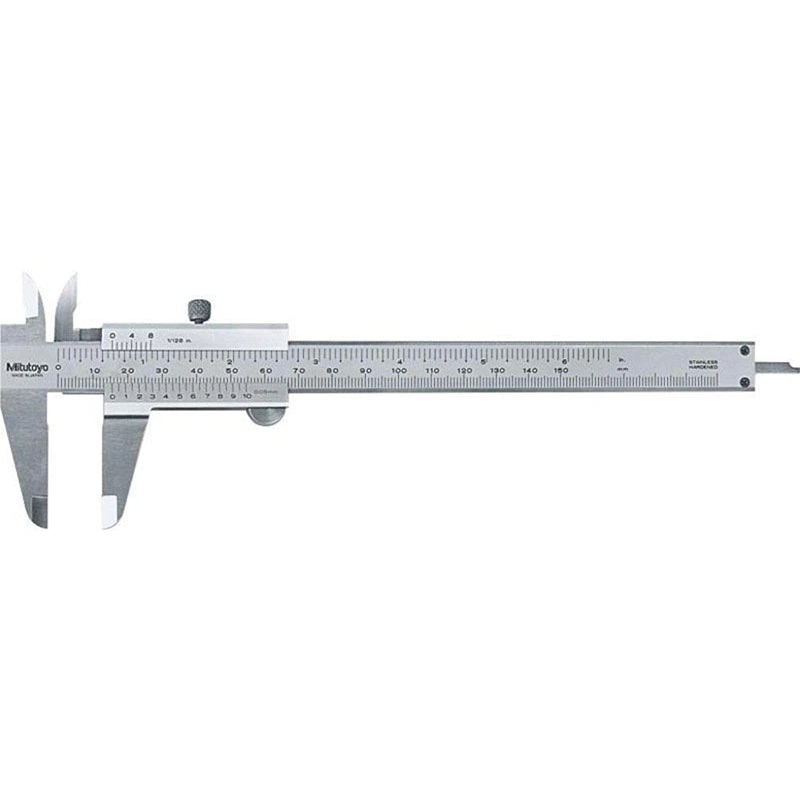

0-150/0.02mm Vernier Caliper (Best Vcal)

150 AED (Incl 5 VAT)

-

0-200/0.02mm Vernier Caliper (Best Vcal)

175 AED (Incl 5 VAT)

-

0-300/0.02mm Vernier Caliper (Best Vcal)

325 AED (Incl 5 VAT)

-

COMBI421 Multifunction Tester

6800 AED (Incl 5 VAT)

-

M70 1000V Insulation and Continuity

2400 AED (Incl 5 VAT)

-

AC/DC TRMS 1000A Clamp Meter with Integrated Thermal Imager

3775 AED (Incl 5 VAT)

-

Open Jaws TRMS Clamp Meter -200AC

735 AED (Incl 5 VAT)

-

PV-ISOTEST – Insulation Meter up to 1500V Solar PV System

8000 AED (Incl 5 VAT)

-

Infrared Thermometer HT3300

380 AED (Incl 5 VAT)

-

Infrared Thermometer 1000C - HT3305

630 AED (Incl 5 VAT)

-

Sound level Meter with Calibrator - HTA102

2200 AED (Incl 5 VAT)

-

HTA103 Thermometer with K/J-Type Probe

700 AED (Incl 5 VAT)

-

Hot Wire Anemometer - HTA105

1800 AED (Incl 5 VAT)

-

Thermo-Hygrometer HTA106

690 AED (Incl 5 VAT)

-

Moisture Meter With Contact & Penetration Probe HTA107

1400 AED (Incl 5 VAT)

-

EVSE Adapter for Electric Vehicle Charger Testing - EV-TEST100

2880 AED (Incl 5 VAT)

-

Multifunction Tester of LV Switchgears and Controlgears FULLTEST3

0 AED (Incl 5 VAT)

-

GSC60 Electrical Safety Tests and Power Quality analysis

0 AED (Incl 5 VAT)

-

Clamp-on Power Quality Analyzer Ht-Instrument HT9020

1800 AED (Incl 5 VAT)

-

50A Step and contact meter HT2055

0 AED (Incl 5 VAT)

-

PQA819 Three-phase Power Quality Analyzer

0 AED (Incl 5 VAT)

-

Professional Insulation Multimeter HT701

2900 AED (Incl 5 VAT)

-

5KV Digital Insulation Tester HT7051

13800 AED (Incl 5 VAT)

-

PQA820 Self-powered three-Phase Power Quality Analyzer

0 AED (Incl 5 VAT)

-

10KV Professional Insulation Tester with Test Voltage HT7052

0 AED (Incl 5 VAT)

-

Multi Function Multimeter RCD Tester- Jupiter

1740 AED (Incl 5 VAT)

-

VEGA78 Power Quality and Energy Consumption Analyzer

0 AED (Incl 5 VAT)

-

Three-Phase Power Quality Analyzer WSP-821w

0 AED (Incl 5 VAT)

-

Self-Powered Three-Phase Power Quality Analyzer WSP-822w

0 AED (Incl 5 VAT)

-

Earth Resistance Tester M71

2875 AED (Incl 5 VAT)

-

M73 Multifunctional Earth Resistance & RCD Tester

2900 AED (Incl 5 VAT)

-

Infrared Thermal Camera - THT200

8100 AED (Incl 5 VAT)

-

Insulation and Continuity professional multimeter - Neptune

1800 AED (Incl 5 VAT)

-

SPEED418 Earth Resistance and RCD Tester

0 AED (Incl 5 VAT)

-

T2100 Clamp meter for measuring earth resistance directly on earth rods compatible with MacrotestG series instruments

0 AED (Incl 5 VAT)

-

Two pole Multi Function Testers HT10

500 AED (Incl 5 VAT)

-

F3000 Clamp meter with flexible Clamp jaws AC 3000A

800 AED (Incl 5 VAT)

-

Professional Digital Multimeter HT39

1250 AED (Incl 5 VAT)

-

Professional TRMS multimeter HT401

1250 AED (Incl 5 VAT)

-

TRMS AC/DC Digital Multimeter - HT61

640 AED (Incl 5 VAT)

-

Digital TRMS AC/DC Multimeter - HT62

740 AED (Incl 5 VAT)

-

Professional TRMS AC+DC DIGITAL MULTIMETER - HT63

800 AED (Incl 5 VAT)

-

Clamp Meter AC/DC 400A - HT4013

460 AED (Incl 5 VAT)

-

TRMS AC/DC Digital Multimeter datalogger - HT64

1680 AED (Incl 5 VAT)

-

Solar PV Digital Multimeter 1500V HT65

780 AED (Incl 5 VAT)

-

Two Pole Voltage Continuity Tester HT7

455 AED (Incl 5 VAT)

-

2-Pole Multifunction Voltage Continuity Tester -HT8

475 AED (Incl 5 VAT)

-

Professional Process Calibrator HT8100

2800 AED (Incl 5 VAT)

-

Mini Clamp Meter 300A AC - HT7004

375 AED (Incl 5 VAT)

-

TRMS Mini Clamp Meter AC/DC 400A - HT7005

575 AED (Incl 5 VAT)

-

AC Clamp Meter for Measuring Leakage currents HT77C

0 AED (Incl 5 VAT)

-

Leakage Current Clamp Meter HT77N

2050 AED (Incl 5 VAT)

-

AC/DC Leakage Current Clamp Meter HT79

0 AED (Incl 5 VAT)

-

TRMS AC/DC Unbreakable Digital Multimeter- IRONMETER

420 AED (Incl 5 VAT)

-

Professional TRMS Clamp Meter 600A HT9014

580 AED (Incl 5 VAT)

-

Digital Clamp Meter 1000 Amp AC/DC HT9021

1100 AED (Incl 5 VAT)

-

Power Quality Clamp Meter - HT9023

1900 AED (Incl 5 VAT)

-

AC/DC Current Clamp with Datalogger HT9025

1900 AED (Incl 5 VAT)

-

AC/DC TRMS Clamp Meter 600A - HT9015

800 AED (Incl 5 VAT)

-

PCE-779N Infrared thermometer

625 AED (Incl 5 VAT)

-

PCE-889B Infrared Thermometer

525 AED (Incl 5 VAT)

-

pH meter PCE-PH 22

520 AED (Incl 5 VAT)

-

Sound Level Meter PCE-MSL 1

160 AED (Incl 5 VAT)

-

10 kV Digital Insulation Tester MD10KVR

15655 AED (Incl 5 VAT)

-

TM25R High Frequency Earth Ground Tester

31500 AED (Incl 5 VAT)

-

100A Digital Micro-Ohmmeter MPK102e

0 AED (Incl 5 VAT)

-

5kV Digital Insulation Tester MD5060x

9375 AED (Incl 5 VAT)

-

200A High Current Micro-Ohmmeter MPK203x

17200 AED (Incl 5 VAT)

-

200A Digital Micro-Ohmmeter MPK204e

17800 AED (Incl 5 VAT)

-

200A High Current Micro-Ohmmeter MPK215e

0 AED (Incl 5 VAT)

-

10A Low resistance Ohmmeter MPK256

11800 AED (Incl 5 VAT)

-

10A Micro Ohmmeter 0.1µO Resolution MPK257

0 AED (Incl 5 VAT)

-

K Type Thermometer - 8802 AZ

440 AED (Incl 5 VAT)

-

Thermo Hygrometer with Probe 8726 AZ

400 AED (Incl 5 VAT)

-

Advanced Thermal Imaging Camera Hikmicro M30

10200 AED (Incl 5 VAT)

-

Thermal Imaging Camera Hikmicro M10

4600 AED (Incl 5 VAT)

-

Wireless Anemometer Navis WR3

1400 AED (Incl 5 VAT)

-

Thermography Camera Hikmicro B1L

1610 AED (Incl 5 VAT)

-

Force Gauge PCE-FM 500N

1940 AED (Incl 5 VAT)

-

Digital Anemometer 8916 AZ

780 AED (Incl 5 VAT)

-

Gloss Meter PCE-GM 60Plus

1400 AED (Incl 5 VAT)

-

Cable Detector PCE-CL 10

1850 AED (Incl 5 VAT)

-

Colorimeter PCE-XXM 30

1250 AED (Incl 5 VAT)

-

Temperature Humidity Datalogger with Touchscreen PCE-HT 300

1740 AED (Incl 5 VAT)

-

Dissolved Oxygen meter PCE-DOM 10

980 AED (Incl 5 VAT)

-

ORP-Tester PCE-ORP 3

750 AED (Incl 5 VAT)

-

Digital Moisture Meter - DL7108

420 AED (Incl 5 VAT)

-

Solar Power Meter- 860042

840 AED (Incl 5 VAT)

-

Chroma Light Meter - 850011

1600 AED (Incl 5 VAT)

-

Weather Station PCE-FWS 20N

630 AED (Incl 5 VAT)

-

Video Borescope Inspection Camera - PCE-VE 180

945 AED (Incl 5 VAT)

-

Leak Detector PCE-LD 1

880 AED (Incl 5 VAT)

-

Pocket Humidity Anemometer - 8918AZ

580 AED (Incl 5 VAT)

-

Handheld Anemometer - Windy 6

480 AED (Incl 5 VAT)

-

EVSE Safety Testing - COMBI521EV

9200 AED (Incl 5 VAT)

-

Electric Vehicle Charging Station EVSE Tester - MACROEVTEST

12800 AED (Incl 5 VAT)

-

Handheld FTTx Fiber Fusion Splicer X500

4800 AED (Incl 5 VAT)

-

OTDR SHINHO X-1100

9450 AED (Incl 5 VAT)

-

Multifunction RCD Insulation Tester EASYTEST

4400 AED (Incl 5 VAT)

-

Heat Stress Monitor - 87785 AZ

3200 AED (Incl 5 VAT)

-

Air quality meter Particle Counter PCE-RCM 16

1080 AED (Incl 5 VAT)

-

Soil pH Meter - PCE-PH20S

760 AED (Incl 5 VAT)

-

Cable and pipe locator Success AG-309.15G

14100 AED (Incl 5 VAT)

-

Hikmicro G40 - Professional Thermography Camera

21000 AED (Incl 5 VAT)

-

Professional Thermography Camera Hikmicro G60

26000 AED (Incl 5 VAT)

-

Multifunction Process Calibrator 4-20mA Current Generator - HT8051

2500 AED (Incl 5 VAT)

-

MGT-P Portable Multi Gas Detector

1600 AED (Incl 5 VAT)

-

Hot Wire Anemometer - PCE-423N

770 AED (Incl 5 VAT)

-

Wireless Telescopic Anemometer - PCE-HWA 20BT

840 AED (Incl 5 VAT)

-

Decibel Meter – Pulsar Nova Class 1

13450 AED (Incl 5 VAT)

-

Pump Suction Oxygen Gas Detector Purge Monitor- GT-903-JM (O2)

2840 AED (Incl 5 VAT)

-

Leeb Hardness Tester NOVOTEST T-D2

3800 AED (Incl 5 VAT)

-

AlcoMate Prestige AL6000 Breathalyzer Alcohol Tester

620 AED (Incl 5 VAT)

-

Ultrasonic Thickness Gauge NOVOTEST UT-1M

3000 AED (Incl 5 VAT)

-

Ultrasonic Thickness Gauge NOVOTEST UT-1M-IP

4600 AED (Incl 5 VAT)

-

Vibration Meter Pen NOVOTEST NVS P1

2400 AED (Incl 5 VAT)

-

Pocket Anemometer Heat Stress Meter - 8909AZ

735 AED (Incl 5 VAT)

-

Thermography Camera Hikmicro B20

2300 AED (Incl 5 VAT)

-

Irradiation Measurement Reference Cell - HT304N

4200 AED (Incl 5 VAT)

-

Temperature Weather Meter Zoglab - Artist

458 AED (Incl 5 VAT)

-

Thermo Hygrometer Zoglab - Smart

220 AED (Incl 5 VAT)

-

Handheld Weather Station HWS1000-Ltd

3200 AED (Incl 5 VAT)

-

Handheld Weather Station HWS1000-Std

3600 AED (Incl 5 VAT)

-

Force Gauge PCE-PFG 100

1820 AED (Incl 5 VAT)

-

Digital Storage Oscilloscope 100 MHz - BK2194

3750 AED (Incl 5 VAT)

-

Digital Storage Oscilloscope 100MHz, 2GSa/s - BK2565B

10200 AED (Incl 5 VAT)

-

Dry Ice Temperature USB Data logger 88165 AZ

520 AED (Incl 5 VAT)

-

Contact & Non-Contact Food thermometer PCE-IR 80

260 AED (Incl 5 VAT)

-

Sound Level Meter with built-in data-logging PCE-322A

900 AED (Incl 5 VAT)

-

Heat Stress Meter WBGT Datalogger - 87786 AZ

750 AED (Incl 5 VAT)

-

WBGT Meter with Heat Index - 87784 AZ

520 AED (Incl 5 VAT)

-

CO2 Monitor - 7729AZ

630 AED (Incl 5 VAT)

-

Ultra Low Temperature Recorder with RTD Pt1000 Probe 88164 AZ

420 AED (Incl 5 VAT)

-

Portable Leeb Hardness Tester Adelix ADL D100

4600 AED (Incl 5 VAT)

-

Digital penetration thermometer DT-501P

900 AED (Incl 5 VAT)

-

Digital surface thermometer DT-501S

980 AED (Incl 5 VAT)

-

Digital thermometer DT-504

780 AED (Incl 5 VAT)

-

Leeb Hardness Tester NOVOTEST T-D3

5200 AED (Incl 5 VAT)

-

Combined Hardness Tester NOVOTEST T-UD3

10800 AED (Incl 5 VAT)

-

Non Contact Forehead Infrared Thermometer - 8826

60 AED (Incl 5 VAT)

-

Digital Fuel Flow Meter - Tokico FGB

3200 AED (Incl 5 VAT)

-

Min/Max Push Button Thermometer - 736690

120 AED (Incl 5 VAT)

-

Multigas Detector Crowcon T4

1720 AED (Incl 5 VAT)

-

Thermal Pocket Camera - Hikmicro Pocket 2

2100 AED (Incl 5 VAT)

-

Multigas Detector Crowcon GasPro

2675 AED (Incl 5 VAT)

-

Magnetic Flaw Detector Magnetic Yoke NOVOTEST MPD-DC

1800 AED (Incl 5 VAT)

-

Wall Metal Stud Detector HT36

320 AED (Incl 5 VAT)

-

Stud Wall Detector DL1093

340 AED (Incl 5 VAT)

-

Voltage Continuity Tester DL6780

180 AED (Incl 5 VAT)

-

Multimeter Test Leads 4324-2

120 AED (Incl 5 VAT)

-

Wall Mounted Infrared Thermometer 800113

320 AED (Incl 5 VAT)

-

Indoor Outdoor Digital Temperature Monitor 800040

220 AED (Incl 5 VAT)

-

Hioki Battery Tester BT3554-51

7960 AED (Incl 5 VAT)

-

Hioki Battery Tester BT3554-52

8400 AED (Incl 5 VAT)

-

Alcohol Tester AlcoMate Premium AL7000

740 AED (Incl 5 VAT)

-

Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST

3800 AED (Incl 5 VAT)

-

Analog Earth Resistance Tester Hioki FT3151

1600 AED (Incl 5 VAT)

-

Digital Radiation Detector 840023

1800 AED (Incl 5 VAT)

-

Moisture Meter with Psychrometer 850003

980 AED (Incl 5 VAT)

-

AC/DC Clamp meter with iFlex Clamp 3000A

1700 AED (Incl 5 VAT)

-

Food Hygiene Temperature Meter PCE-ST 1

240 AED (Incl 5 VAT)

-

Resistance Meter Hioki RM3548

5200 AED (Incl 5 VAT)

-

Temperature Humidity Datalogger - Mini TH

450 AED (Incl 5 VAT)

-

Handheld Tachometer PCE-T 238

840 AED (Incl 5 VAT)

-

7.4KW AC EV Charger

2400 AED (Incl 5 VAT)

-

Oldham Combustible Gas Detector LEL - OLCT100

3200 AED (Incl 5 VAT)

-

Oldham Toxic Gas Detector H2S - OLCT100

3400 AED (Incl 5 VAT)

-

Temperature Humidity Datalogger with Email Alert - DSR-TH

1880 AED (Incl 5 VAT)

-

Maxlogic Marine Type Conventional Fire Alarm Panel 16 Zone

4800 AED (Incl 5 VAT)

-

8 Zone Marine Approved Conventional Fire Alarm Panel

3800 AED (Incl 5 VAT)

-

TM200CE24R Controller M200 24 IO relay+Ethernet

3100 AED (Incl 5 VAT)

-

Indoor Air Quality Monitor PCE-CMM 8

750 AED (Incl 5 VAT)

-

CO2 Analyzer PCE-CMM 5

730 AED (Incl 5 VAT)

-

Vibrometer Meter ADL-P3

2000 AED (Incl 5 VAT)

-

Vibration meter ADL-M20

2700 AED (Incl 5 VAT)

-

Ultrasonic Thickness Gauge ADL-UT20

3600 AED (Incl 5 VAT)

-

Conventional Smoke Detector Mavigaurd ML-2110/M

160 AED (Incl 5 VAT)

-

Conventional Heat Detector Mavigaurd ML-2130/M

160 AED (Incl 5 VAT)

-

Pressure Switch Finetek SQ275

240 AED (Incl 5 VAT)

-

Tractel dynafor Industrial 20T Load Cell

12800 AED (Incl 5 VAT)

-

Tractel dynafor Industrial 12.5T Crane Scale

12000 AED (Incl 5 VAT)

-

.webp)

High Temperature Infrared Thermometer 1880°C - TA603D

1600 AED (Incl 5 VAT)

-

Industrial Infrared Thermometer Gun 2200°C - TA603E

1980 AED (Incl 5 VAT)

-

Air Quality Meter Datalogger- HCHO TVOC C6H6 TA7116B

1400 AED (Incl 5 VAT)

-

Terasaki Tempower 2 ACB - AR216S 1600A 3P LSI AGR11 65kA

19000 AED (Incl 5 VAT)

-

Terasaki Tempower 2 ACB - AR325S 2500A 3P LSI AGR11 85kA

26000 AED (Incl 5 VAT)

-

Tembreak 2 MCCB- S1600-NE 3P 1600A Terasaki 570209

11200 AED (Incl 5 VAT)

-

TemBreak 2 MCCB 530401 S1000-NE 3P 1000A

6900 AED (Incl 5 VAT)

-

Terasaki Tembreak 2 MCCB 255243 S125-GJ 3P 100A

1050 AED (Incl 5 VAT)

-

Tembreak 2 MCCB Thermal Magnetic S250-NJ 3P 250A FC 312038

1250 AED (Incl 5 VAT)

-

Ultrasonic Contact Impedance UCI Hardness Tester T-U2

4400 AED (Incl 5 VAT)

-

Tractel Dynafor Pro 50T dynamometer

34900 AED (Incl 5 VAT)

-

Tractel Dynamometer Dynafor Pro 100T Load Cell

0 AED (Incl 5 VAT)

-

Tractel Dynamometer Dynafor Pro 250T

0 AED (Incl 5 VAT)

-

Air Quality Meter Datalogger CombiAQM

3600 AED (Incl 5 VAT)

-

MeaTest Multi Product Calibrator 9010

86000 AED (Incl 5 VAT)

-

MeaTest 9010+ Multifunction Calibrator

0 AED (Incl 5 VAT)

-

Borescope Inspection Camera NTS300

1400 AED (Incl 5 VAT)

-

Long Range Wireless Anemometer Datalogger WL12X/WS

2200 AED (Incl 5 VAT)

-

Wireless Anemometer Datalogger WL12/WS

1900 AED (Incl 5 VAT)

-

Wireless Anemometer Wind Direction Datalogger WL12/WSD

2600 AED (Incl 5 VAT)

-

Wireless Wind Datalogger with Alarm W410

3420 AED (Incl 5 VAT)

-

Golf Rangefinder Monocular Camera 600M PF210

1100 AED (Incl 5 VAT)

-

Hunting Monocular Camera Laser Rangefinder PF210

945 AED (Incl 5 VAT)

-

Multifunction wheel Curve laser distance meter R2B

880 AED (Incl 5 VAT)

-

Green Laser Distance Meter S8G

820 AED (Incl 5 VAT)

-

Cross Laser Level L52G

520 AED (Incl 5 VAT)

-

Ozone Air Quality Meter EN1300

640 AED (Incl 5 VAT)

-

Type K Surface Thermometer Probe 800070

340 AED (Incl 5 VAT)

-

Surface Thermometer Probe 800073

240 AED (Incl 5 VAT)

-

Alcohol Detector ACT5000

525 AED (Incl 5 VAT)

-

Smart Temperature Humidity Monitor external Probe T306

160 AED (Incl 5 VAT)

-

Smart Temperature Humidity Monitor T301

120 AED (Incl 5 VAT)

-

Battery Tester BT528A

4800 AED (Incl 5 VAT)

-

Humidity Temperature Monitor external Probe TH3010E

210 AED (Incl 5 VAT)

-

Temperature Humidity Monitor TH3010

190 AED (Incl 5 VAT)

-

LCR Tester LCR826

1800 AED (Incl 5 VAT)

-

Temperature Humidity Meter TC100A

300 AED (Incl 5 VAT)

-

Portable Ultrasonic Flowmeter P117

9400 AED (Incl 5 VAT)

-

Clamp-on Ultrasonic Flow Meter P118i-PH020

17800 AED (Incl 5 VAT)

-

Ultrasonic Heat Meter BTU for Energy Metering

4200 AED (Incl 5 VAT)

-

Industrial multigas detector with particle counter

10800 AED (Incl 5 VAT)

-

Thermal Imaging Camera Hikmicro B2L

1640 AED (Incl 5 VAT)

-

Desktop CO2 Air Quality Monitor SI7100

780 AED (Incl 5 VAT)

-

Air Quality Monitor Particle Counter SI7400

820 AED (Incl 5 VAT)

-

Indoor Outdoor Weather Station SI9100

760 AED (Incl 5 VAT)

-

Marine Anemometer Sensor Wind Speed & Direction Mi9000S

7900 AED (Incl 5 VAT)

-

Meat Thermometer KT100

320 AED (Incl 5 VAT)

-

Smart WiFi Temperature Humidity Datalogger T401

220 AED (Incl 5 VAT)

-

Carbon Monoxide Monitor SI3700

350 AED (Incl 5 VAT)

-

Food Thermometer FT20

120 AED (Incl 5 VAT)

-

Thermo hygrometer and air pressure with data logger TH3052

340 AED (Incl 5 VAT)

-

Digital Thermometer Datalogger PT100 T516

540 AED (Incl 5 VAT)

-

Hygrometer datalogger with CO2 TH3042

420 AED (Incl 5 VAT)

-

Digital Tachometer SI510

400 AED (Incl 5 VAT)

-

4 Channel Digital Thermometer Datalogger T446

900 AED (Incl 5 VAT)

-

Digital Tachometer SI520

700 AED (Incl 5 VAT)

-

Digital Alarm Temperature Humidity Thermometer A2000EX

640 AED (Incl 5 VAT)

-

2 Channel Digital Thermometer Datalogger T422

630 AED (Incl 5 VAT)

-

Large Display Wall Mounted Temperature Humidity Monitor

1200 AED (Incl 5 VAT)

-

Digital Thermometer Datalogger T412

520 AED (Incl 5 VAT)

-

Digital Thermometer T410

420 AED (Incl 5 VAT)

-

Handheld Thermal Monocular Camera HIKMICRO LYNX LC06

1880 AED (Incl 5 VAT)

-

Alarm Thermo-Hygrometer A2000TH

600 AED (Incl 5 VAT)

-

Multiuse Temperature and Humidity data logger with LCD TH2010

180 AED (Incl 5 VAT)

-

GSM Temperature & Humidity datalogger SMS Alarm S500EX

1400 AED (Incl 5 VAT)

-

CO2 Air Quality Monitor SI5200

720 AED (Incl 5 VAT)

-

NH3 Ammonia Gas Monitor SI3750

630 AED (Incl 5 VAT)

-

Secondary Current Injection Test Set 200ADM-P

0 AED (Incl 5 VAT)

-

Pulse Holiday Detector NOVOTEST SPARK-1

8200 AED (Incl 5 VAT)

-

Cable locator Success CBI-309G

7800 AED (Incl 5 VAT)

-

Infrared Thermometer SI330

300 AED (Incl 5 VAT)

-

Pipe and Cable Locator PL-VF10

15800 AED (Incl 5 VAT)

-

Multifunction Insulation Loop Impedance Tester Combi521

6400 AED (Incl 5 VAT)

-

Advanced Multifunction Installation Tester MACROTESTG3

9200 AED (Incl 5 VAT)

-

850071-Environmental Quality SD Card Logger

1050 AED (Incl 5 VAT)

-

Pneumatic Pressure Test Pump LR-Cal LPP 40

4200 AED (Incl 5 VAT)

-

Hydraulic Pressure Test Pump LPP 700

6000 AED (Incl 5 VAT)

-

Portable Multifunction Temperatur Calibrator LR-Cal LTC 100

6200 AED (Incl 5 VAT)

-

DigitalThermometer Datalogger PT1000 – T518

600 AED (Incl 5 VAT)

-

HD Sewer Pipe Inspection Camera PICS2150 50 Meter Cable

8800 AED (Incl 5 VAT)

-

Handheld 3 Channel Particle Counter TC8100

1600 AED (Incl 5 VAT)

-

Handheld 6 Channel Particle Counter TC8200

2400 AED (Incl 5 VAT)

-

Laser Distance Meter 70M SI1172

420 AED (Incl 5 VAT)

-

Green Laser Distance Meter 120M SI1180

760 AED (Incl 5 VAT)

-

Wireless Wind Speed & Wind Direction Anemometer WR5/WSD

2480 AED (Incl 5 VAT)

-

WiFi Temperature Humidity Datalogger Edge500

800 AED (Incl 5 VAT)

-

WiFi Sound Level Meter Edge500S

1600 AED (Incl 5 VAT)

-

WiFi CO2 Meter EdgeMeter500C

1300 AED (Incl 5 VAT)

-

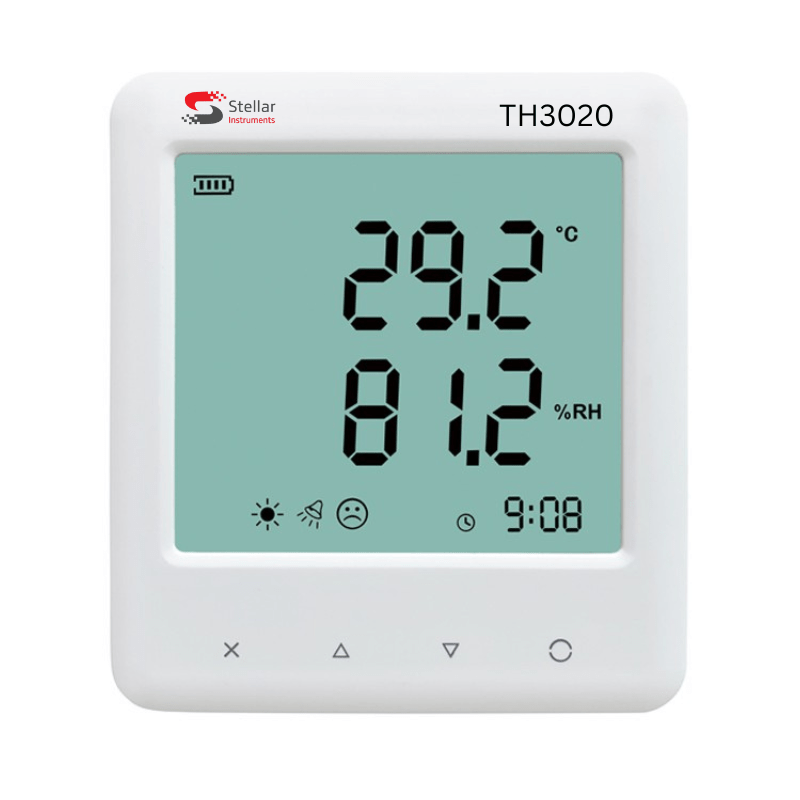

Temperature Humidity Datalogger TH3020

250 AED (Incl 5 VAT)

-

Soil Moisture Meter MC288

900 AED (Incl 5 VAT)

-

Grain Moisture Meter MC289

630 AED (Incl 5 VAT)

-

Infrared Belt Tension Meter BT290

2700 AED (Incl 5 VAT)

-

Gauss Meter GM280

1800 AED (Incl 5 VAT)

-

Vibration Meter VM370

2600 AED (Incl 5 VAT)

-

Turbidity Meter 860040

1830 AED (Incl 5 VAT)

-

Earth Ground Tester GEO416

4200 AED (Incl 5 VAT)

-

Digital Water Quality Meter 7 in 1 BLEC600

700 AED (Incl 5 VAT)

-

PH EC TDS Temp PH Meter BLE9908

250 AED (Incl 5 VAT)

-

PH EC TDS Temp Salt Meter BLE9909

380 AED (Incl 5 VAT)

-

Wi-Fi Pool PH Salinity Temperature Controller 3 in 1 W2825

900 AED (Incl 5 VAT)

-

Wi-Fi Pool PH TDS Temperature Controller 3 in 1 W2826

890 AED (Incl 5 VAT)

-

Digital PH EC Controller Temperature 3 in 1 W2823

850 AED (Incl 5 VAT)

-

Digital Multimeter with iFlex HT65i

1600 AED (Incl 5 VAT)

-

Pipe Inspection Videoscope System PICS3100 100M

18800 AED (Incl 5 VAT)

-

WiFi Dew Point Meter EdgeMeter500D

1900 AED (Incl 5 VAT)

-

Fuel Dispenser Measuring Can 10L

1400 AED (Incl 5 VAT)

-

Circuit Breaker Analyser with Printer 3-Contact CIBRE-30

52800 AED (Incl 5 VAT)

-

Single Phase TURA-01 BLUE TTR Tester with Built-in Bluetooth & Printer

0 AED (Incl 5 VAT)

-

Single Phase TURA-01 TTR Tester with Printer

0 AED (Incl 5 VAT)

-

TURA-X True Three-Phase Transformer TTR with Built-in Printer

0 AED (Incl 5 VAT)

-

TURA-03B BLUE 250V Three-Phase TTR with Battery, Bluetooth & Printer

0 AED (Incl 5 VAT)

-

TURA-03B 250V Three-Phase Transformer Turns Ratio Tester with Built-in Battery & Printer

0 AED (Incl 5 VAT)

-

TURA-03 BLUE 250V Three-Phase Transformer Turns Ratio Tester with Built-in Bluetooth & Printer

0 AED (Incl 5 VAT)

-

Three-Phase Transformer TTR TURA-03 250V with Built-in Printer

48800 AED (Incl 5 VAT)

-

TRIORES-20 20A Fully Automatic Three-phase Winding Resistance Tester with Built-in Printer

0 AED (Incl 5 VAT)

-

WINRES-20B BLUE 20A Winding Resistance Tester With Battery, Bluetooth & Printer

0 AED (Incl 5 VAT)

-

Concrete Cover Meter NOVOTEST Rebar Detector (NEW GENERATION 2020)

7200 AED (Incl 5 VAT)

-

WINRES-20 BLUE 20A Winding Resistance Tester with Bluetooth & Printer

0 AED (Incl 5 VAT)

-

Strength Meter NOVOTEST IPSM

9000 AED (Incl 5 VAT)

-

Ultrasonic Flaw Detector NOVOTEST UD3701

17800 AED (Incl 5 VAT)

-

WINRES-20B 20A Winding Resistance Tester with Battery & Printer

0 AED (Incl 5 VAT)

-

Ultrasonic Flaw Detector NOVOTEST UD2303

14000 AED (Incl 5 VAT)

-

Winding Resistance Tester 20A WINRES-20 with Built-in Printer

54000 AED (Incl 5 VAT)

-

Portable Appliance Tester PAT DLPT2+

3700 AED (Incl 5 VAT)

-

Digital Micro-ohmmeter HARES 100A

0 AED (Incl 5 VAT)

-

GSM Wireless Network SMS Temperature Humidity Datalogger SI5600

1600 AED (Incl 5 VAT)

-

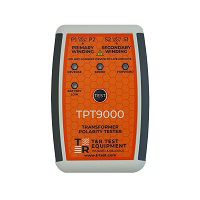

Transformer Polarity Tester TPT9000

3600 AED (Incl 5 VAT)

-

Digital Micro-ohmmeter HARES 200A

0 AED (Incl 5 VAT)

-

Digital Micro-ohmmeter HARES 300A

0 AED (Incl 5 VAT)

-

Circuit Breaker Analyser with Printer 6-Contact CIBRE-60

0 AED (Incl 5 VAT)

-

Circuit Breaker Timer with Printer 3-Contact CIBRE-L3

32000 AED (Incl 5 VAT)

-

Circuit Breaker Timer with Printer 6-Contact CIBRE-L6

0 AED (Incl 5 VAT)

-

Suwi Series Combined Multifunction Test and Measurement Equipment

0 AED (Incl 5 VAT)

-

Vacuum Bottle Tester VABO-80B 80 kV Vacuum Bottle Tester with built-in Battery & Printer

0 AED (Incl 5 VAT)

-

Portable Vibration Meter Adelix M10

1500 AED (Incl 5 VAT)

-

2000A True RMS AC DC Clamp Meter SI6470

630 AED (Incl 5 VAT)

-

High Accuracy AC Current Leakage Clamp Meter SI6600

525 AED (Incl 5 VAT)

-

Handheld Densitometer Xograph Digit X

5600 AED (Incl 5 VAT)

-

Industrial Articulating Inspection Camera PIE1630 3Meter Probe

10800 AED (Incl 5 VAT)

-

Video borescope Inspection Camera PIE1610 1Meter Probe

5400 AED (Incl 5 VAT)

-

Ground Penetrating Radar (GPR)PVC Locator AML PRO

37800 AED (Incl 5 VAT)

-

Cable Locator Radiodetection RD7200

9800 AED (Incl 5 VAT)

-

Cable Detector Radiodetection RD8200

15900 AED (Incl 5 VAT)

-

Semi Solid Meat Cheese pH Meter SI220

2100 AED (Incl 5 VAT)

-

Digital Pocket pH Meter SI360

250 AED (Incl 5 VAT)

-

Digital Salinity Meter SI362

350 AED (Incl 5 VAT)

-

Step Wedge Ultrasonic Calibration Block 10-20-30-40-50MM

1200 AED (Incl 5 VAT)

-

Ultrasonic Thickness Calibration Step Wedge Block 10-20-40-60-80-100MM

1580 AED (Incl 5 VAT)

-

Low & medium voltage dead cables identifier JUPITER X

33800 AED (Incl 5 VAT)

-

Live LV Low Voltage Energized Cable Identifier LCI-400

27500 AED (Incl 5 VAT)

-

Phase and feeder on line controller m.PAD-DS

44500 AED (Incl 5 VAT)

-

Plastic Gas Pipe Locator GAS TRACKER2

0 AED (Incl 5 VAT)

-

Handheld Digital Chlorine Meter SI365

1000 AED (Incl 5 VAT)

-

Dissolved Oxygen Meter SI368

1040 AED (Incl 5 VAT)

-

Digital Refractometer Brix 0~50% SI545

900 AED (Incl 5 VAT)

-

Digital Refractometer Brix 0~95% SI546

1100 AED (Incl 5 VAT)

-

Class 1 Sound Level Meter Kit - Optimus Red

12500 AED (Incl 5 VAT)

-

Sound Level Meter with Datalogging SI340

880 AED (Incl 5 VAT)

-

Multimeter Test Lead 4324-2

120 AED (Incl 5 VAT)

-

Digital Dynamometer 20750K

1800 AED (Incl 5 VAT)

-

Vibration Analyzer Adelix MS30

6000 AED (Incl 5 VAT)

-

EMAT Thickness Gauge NOVOTEST UT-3M-EMA

14800 AED (Incl 5 VAT)

-

Pipe Inspection Camera PICS1230 30 Meter Cable

6500 AED (Incl 5 VAT)

-

Pipe Inspection Camera PICS2250 50 Meter Cable

9400 AED (Incl 5 VAT)

-

Class 1 Sound Level Meter Kit With Datalogging 1:1 Octaves NR/NC - Optimus Red

19750 AED (Incl 5 VAT)

-

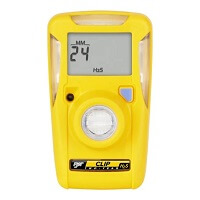

BW Technologies BW Clip Single Gas H2S Detector

0 AED (Incl 5 VAT)

-

Cable Avoidance Tool CScope DXL3

4700 AED (Incl 5 VAT)

-

Email Alert Temperature and Humidity Datalogger DSR-TH

1480 AED (Incl 5 VAT)

-

Multifunction Installation Tester HT Instruments Combi420

5800 AED (Incl 5 VAT)

-

Coating Thickness Gauge NOVOTEST TP-2020

3000 AED (Incl 5 VAT)

-

Portable Ultrasonic Flowmeter UFP-20 Sensor Kit 2

18000 AED (Incl 5 VAT)

-

Ultrasonic Flowmeter for GRP HDPE Pipe UFP-2 Sensor Kit 7

23400 AED (Incl 5 VAT)

-

IP68 HACCP Digital Industrial Thermometer Temp50

260 AED (Incl 5 VAT)

-

Digital Industrial Probe Thermometer FT50

200 AED (Incl 5 VAT)

-

Mini Sound Level Meter SLM10

150 AED (Incl 5 VAT)

-

Mini WBGT Meter WBGT20

500 AED (Incl 5 VAT)

-

Pipe Inspection Camera with Self Leveling 50M PICS2255

11800 AED (Incl 5 VAT)

-

Pipe Inspection Camera PICS1130 30 Meter Cable

6200 AED (Incl 5 VAT)

-

Professional Articulating Inspection Videoscope Camera PIE2630

10800 AED (Incl 5 VAT)

-

Infrared Thermal Image Videoscope TIV16510 with 1M probe

11800 AED (Incl 5 VAT)

-

Industrial Articulating Videoscope Camera 3.9mm dia Probe

11500 AED (Incl 5 VAT)

-

Multifunction Cable Length Tester Noyafa NF-8601W

900 AED (Incl 5 VAT)

-

Optical Wire Meter OPM Visual Fault Locator PoE tester Network Cable tester NF-8508

950 AED (Incl 5 VAT)

-

Coating Thickness Gauge GT10

3600 AED (Incl 5 VAT)

-

Sewer Inspection Videoscope with Integrated Pan Tilt Camera PICS4100

29000 AED (Incl 5 VAT)

-

Mini CO CO2 Monitor SI3720

520 AED (Incl 5 VAT)

-

Trusted T7 Real Time Monitoring and Data Tracking

1800 AED (Incl 5 VAT)

-

Radiodetection Cable Avoidance Tool CAT4

5800 AED (Incl 5 VAT)

-

Radiodetection Cable Avoidance Tool CAT4+

6700 AED (Incl 5 VAT)

-

Radiodetection CAT4+ & Genny4 Cable Locator Kit

11400 AED (Incl 5 VAT)

-

Radiodetection RD8200 Cable & Pipe Locator Kit

27000 AED (Incl 5 VAT)

-

Radiodetection RD7200 Cable & Pipe Locator Kit

21000 AED (Incl 5 VAT)

-

CAT4 Genny Cable & Pipe Locator

10200 AED (Incl 5 VAT)

-

Hikmicro M11W Handheld Thermography Camera

3600 AED (Incl 5 VAT)

-

Hikmicro M20W Handheld Thermography Camera

6200 AED (Incl 6480 VAT)

-

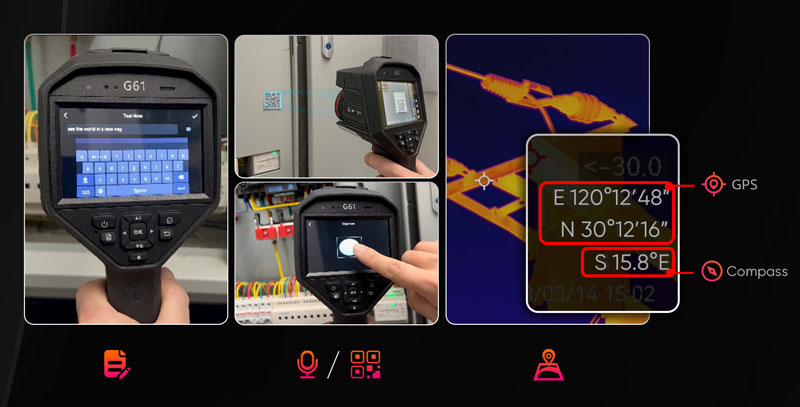

HIKMICRO G61 Handheld Thermal Camera

28000 AED (Incl 5 VAT)

-

Light Meter SI344

440 AED (Incl 5 VAT)

-

Metrohm High Voltage Indicators HVI F0357A

5600 AED (Incl 5 VAT)

-

Metrohm Live Line Indicator LLI

8200 AED (Incl 5 VAT)

-

Trusted T8 LTE Flight-approved 2G 3G Temperature Tracker

2000 AED (Incl 5 VAT)

-

Trusted T9LTE Temperature GPS Motion Shock tracker

2300 AED (Incl 5 VAT)

-

Senko SGT-P H2S Single Gas Detector

460 AED (Incl 5 VAT)

-

Conductivity Meter CT20

250 AED (Incl 5 VAT)

-

Total dissolved solids TDS Meter TDS10

300 AED (Incl 5 VAT)

-

Intrinsically Safe Thermal Camera Hikmicro BX20

5300 AED (Incl 5 VAT)

-

Solar PV I-V curve measurements up to 1500V and 40A IV600

48000 AED (Incl 5 VAT)

-

Firefighting Thermal Camera Hikmicro FT31

8900 AED (Incl 5 VAT)

-

Advanced handheld thermal camera Hikmicro G41

22000 AED (Incl 5 VAT)

-

HIKMICRO M20 Handheld Thermography Camera

7700 AED (Incl 5 VAT)

-

Kestrel 5400 Heat Stress Tracker HST Pro with Compass and LiNK Vane Mount

2600 AED (Incl 5 VAT)

-

Kestrel 5400 Heat Stress Tracker

2260 AED (Incl 5 VAT)

-

Kestrel 5000 Environmental Meter

1200 AED (Incl 5 VAT)

-

Kestrel 5500 Weather Meter with LiNK Vane Mount

1900 AED (Incl 5 VAT)

-

Kestrel 5200 Professional Environmental Meter

1220 AED (Incl 5 VAT)

-

Kestrel 3500 Weather Meter

1000 AED (Incl 5 VAT)

-

Kestrel 2500 Weather Altimeter

800 AED (Incl 5 VAT)

-

Pocket Wind Meter Kestrel 2000

525 AED (Incl 5 VAT)

-

Kestrel 1000 Wind Meter

420 AED (Incl 5 VAT)

-

Sauermann DBM 620 Air Capture Hood

9400 AED (Incl 5 VAT)

-

Combustion analyzer Si-CA 130

5400 AED (Incl 5 VAT)

-

Flue Gas Analyzer Sauermann SiCA 030

3900 AED (Incl 5 VAT)

-

4-20 mA Loop Calibrator PIE 334

4620 AED (Incl 5 VAT)

-

Multifunction Process Calibrator 10-50 mA PIE 850

22000 AED (Incl 5 VAT)

-

RTD and Thermocouple Calibrator PIE 525B

9520 AED (Incl 5 VAT)

-

High Temperature Datalogger HiTEMP10

1400 AED (Incl 5 VAT)

-

M143 Portable Multifunction Calibrator

44000 AED (Incl 5 VAT)

-

Process Calibrator Meatest M160 Precision DC Calibrator

28000 AED (Incl 5 VAT)

-

Meatest M641 Resistance Decade Box RTD Simulator

16000 AED (Incl 5 VAT)

-

Thermo-Anemometer with integrated vane probe LV110

2100 AED (Incl 5 VAT)

-

Thermo-Anemometer with Vane Probe Sauermann Kimo LV130

1700 AED (Incl 5 VAT)

-

Thermo-Anemometer with integrated vane probe LV50

1600 AED (Incl 5 VAT)

-

Vane Thermo-Anemometer SI-VV3

2000 AED (Incl 5 VAT)

-

Hotwire Thermo-Anemometer Kimo VT50

1500 AED (Incl 5 VAT)

-

Hotwire Thermo-Anemometer VT 110

2000 AED (Incl 5 VAT)

-

Hotwire Thermo-Anemometer With integrated hotwire probe SI-VH3

2200 AED (Incl 5 VAT)

-

Gas leak detector Si-CD3

2400 AED (Incl 5 VAT)

-

Multifunction Instrument AMI 310CLA

11900 AED (Incl 5 VAT)

-

Micromanometer (Thermo-Anemo-Manometer) MP210P

4900 AED (Incl 5 VAT)

-

Thermo-Hygrometer-Anemometer VT 210TH

4900 AED (Incl 5 VAT)

-

Thermo Hygrometer with CO2 HQ210P

4300 AED (Incl 5 VAT)

-

Manometer MP 110

1600 AED (Incl 5 VAT)

-

Impermeability Special Manometer for gas network MP 130

3100 AED (Incl 5 VAT)

-

Manometer MP 120

1900 AED (Incl 5 VAT)

-

Digital Differential Pressure Manometer Si-PM3

2500 AED (Incl 5 VAT)

-

Temperature And Differential Pressure Transmitter CP 210-R

2400 AED (Incl 5 VAT)

-

Differential Pressure Transmitter CP 111

1600 AED (Incl 5 VAT)

-

Differential Pressure Transmitter CP 115

1400 AED (Incl 5 VAT)

-

Atmospheric Pressure Transmitter CP 116

1400 AED (Incl 5 VAT)

-

Multifunction Transmitter SI-C320

2600 AED (Incl 5 VAT)

-

NON CONTACT VOLTAGE DETECTOR NCV10

80 AED (Incl 5 VAT)

-

TEMPERATURE HUMIDITY DATALOGGER TagPlus-TH

120 AED (Incl 5 VAT)

-

DESKTOP WALL MOUNTED NOISE METER SI9130

1400 AED (Incl 5 VAT)

-

PIPE INSPECTION CAMERA PIE4215

3800 AED (Incl 5 VAT)

1

-

New Customer ?

Sign in/Up